Automation in American manufacturing is accelerating as factories adopt robots, AI, and smart systems. Explore why it’s rising, how it affects jobs, and what the future holds.

Table of Contents

Introduction: A Quiet Revolution on the Factory Floor

Walk into a modern U.S. factory today and the difference is immediately visible. Robotic arms move with precision, sensors track production in real time, and machines communicate with each other without human input. This is not science fiction—it’s the new reality of Automation in American manufacturing.

Over the past decade, American manufacturers have increasingly turned to automation to remain competitive in a global economy. Rising labor costs, supply chain disruptions, and technological breakthroughs have pushed companies to rethink how goods are produced. While automation has long been part of manufacturing, its scale and sophistication today represent a major shift.

This blog explores why automation is rising, how it’s transforming factories, what it means for workers, and whether it ultimately strengthens or challenges the American manufacturing sector.

What Automation in American Manufacturing Really Means

Automation in manufacturing refers to the use of machines, robotics, software, and artificial intelligence to perform tasks that were once done manually. In the U.S. context, Automation in American factories often focuses on:

- Industrial robots for assembly and welding

- Computer-controlled machines (CNC)

- Automated quality inspection systems

- AI-driven production planning

- Smart sensors and Internet of Things (IoT) devices

The goal is not just speed, but consistency, efficiency, and resilience.

Why Automation Is Accelerating Now

1. Rising Labor Costs and Shortages

Manufacturers across the U.S. face persistent labor shortages, especially for physically demanding or repetitive jobs. At the same time, wages have risen in many regions.

Automation helps fill these gaps. Machines don’t retire, call in sick, or require constant retraining—making them an attractive long-term investment.

2. Global Competition Is Intensifying

American manufacturers compete with countries that often have lower labor costs. To stay competitive without outsourcing production, companies are embracing Automation in American factories to increase productivity and reduce per-unit costs.

This strategy allows firms to keep production domestic while maintaining global price competitiveness.

3. Technology Has Become More Affordable

In the past, automation was expensive and complex, limiting adoption to large corporations. Today, robots and software systems are more modular, scalable, and affordable—even for mid-sized manufacturers.

Cloud computing and AI have lowered barriers, making automation accessible across the industry.

4. Supply Chain Disruptions Changed Priorities

Recent global disruptions exposed the risks of relying too heavily on overseas manufacturing. Automation supports reshoring by making U.S.-based production economically viable again.

For insights on U.S. manufacturing trends, see:

https://www.nam.org

How Automation Is Transforming American Factories

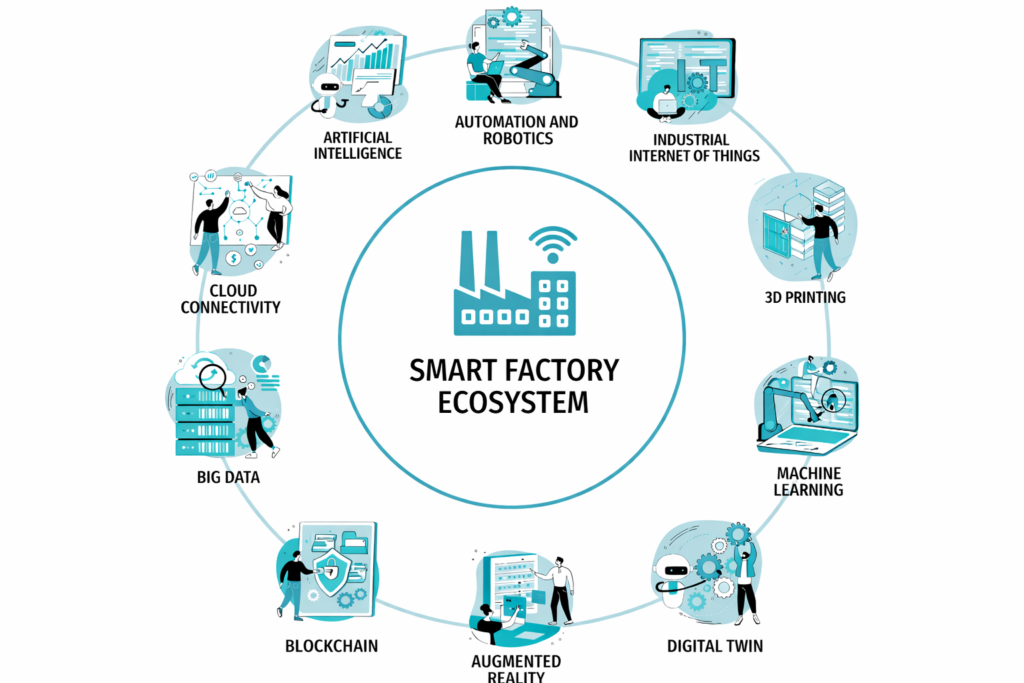

Smarter Production Lines

Modern factories use connected machines that adjust output in real time. If a bottleneck forms, systems automatically reroute workflows.

This flexibility reduces downtime and waste.

Improved Quality Control

Automated vision systems inspect products faster and more accurately than human eyes. Defects are detected earlier, saving costs and improving customer satisfaction.

Predictive Maintenance

Sensors monitor equipment health and predict failures before they occur. This reduces unexpected breakdowns and extends machinery lifespan.

The Impact on Jobs: Fear vs Reality

One of the biggest concerns surrounding Automation in American manufacturing is job loss. While some roles are indeed eliminated, the full picture is more complex.

Jobs That Are Declining

- Repetitive manual tasks

- Low-skill assembly line roles

- Routine inspection jobs

Jobs That Are Growing

- Robotics technicians

- Automation engineers

- Data analysts

- Maintenance specialists

Automation shifts the nature of work rather than eliminating it entirely. The challenge lies in retraining and upskilling workers fast enough.

For workforce data and retraining initiatives, explore:

https://www.bls.gov

Worker Adaptation and Reskilling

Many manufacturers now invest heavily in training programs. Instead of replacing workers, they aim to redeploy them into higher-value roles.

This transition is not always smooth. Older workers may struggle to adapt, while younger workers often embrace technical roles more easily.

Successful automation strategies balance technology adoption with human development.

Small vs Large Manufacturers

Large corporations often lead automation adoption due to greater resources. However, small and medium-sized manufacturers are catching up through:

- Collaborative robots (cobots)

- Leasing automation equipment

- Government-supported modernization programs

This democratization of automation is reshaping the entire manufacturing ecosystem.

Environmental and Efficiency Benefits

Automation also supports sustainability goals.

- Reduced material waste

- Optimized energy use

- Lower emissions through efficient processes

Smarter factories tend to be greener factories.

Challenges Facing Automation in American Manufacturing

Despite its benefits, automation presents real challenges:

High Initial Investment

Even with falling costs, automation requires upfront capital that some firms struggle to secure.

Cybersecurity Risks

Connected factories are vulnerable to cyber threats. Protecting production systems is now a critical concern.

Workforce Resistance

Fear of job loss can create resistance among employees if communication is poor.

Addressing these challenges requires careful planning and transparent leadership.

Government Policy and Support

Federal and state governments increasingly view Automation in American manufacturing as a strategic priority. Support comes in the form of:

- Tax incentives

- Grants for modernization

- Workforce training programs

For policy perspectives, see:

https://www.whitehouse.gov

Is Automation Strengthening American Manufacturing?

In many ways, yes.

Automation has helped:

- Increase domestic production

- Improve global competitiveness

- Enhance supply chain resilience

However, its success depends on inclusive growth. Without proper training and social support, automation risks widening inequality.

The Future Outlook

Automation will continue to expand, but it won’t create “lights-out” factories everywhere. Humans remain essential for creativity, oversight, and problem-solving.

The future of Automation in American manufacturing lies in collaboration—where humans and machines complement each other rather than compete.

Conclusion

The rise of automation marks one of the most significant transformations in American manufacturing history. Driven by labor challenges, technological progress, and global competition, automation is reshaping how goods are made in the United States.

While concerns about jobs are valid, automation also creates opportunities for innovation, higher-skilled work, and economic resilience. The key question is not whether automation will continue—but how effectively America manages the transition.

Consumer Sentiment in the U.S. has ticked up despite ongoing job worries. Explore what’s driving cautious optimism, how Americans are spending, and what it means for the economy.